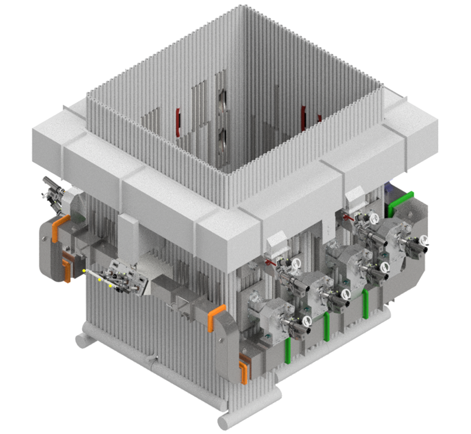

Char Bed Modernization (CBM)

Why Modernize Primary Air Systems?

Liquor droplets dry & burn faster in suspension

Fluidize char bed speeds spray to smelt conversion.

Generates higher thermal inertia to allow more (fuel) liquor spray downwards.

Molten droplets are less buoyant with higher density that reduces carryover.

Low benefit large char beds shields much of the fuel below the surface of the bed.

A hot and low char bed has greater disturbance rejection capability.

Reducing conversion time from char to smelt adds greater safety and throughput capability.

Improved emissions and carryover.

Control complete bed topography.

Maintain hotter char bed.

Eliminate the formation of concentrated flue gases at the center of the furnace.

Improve disturbance rejection capability.

Improve boiler water circulation ratio

We have achieved the contract established goals on 100% of our projects

The current primary air systems are a bit outdated and come with hefty operational and maintenance costs. Originally, they were designed to help with smelt drainage around the bed, back when liquor solids firing ranged from 52% to 63%. During those times, there were high blackout risks, so lots of small openings were needed for manual bed stoking with rods. But things have changed since then.

Nowadays, black liquor has much higher solids concentration, and furnaces are bigger, which means lower furnace temperatures run hotter than they used to in the early days of chemical recovery boilers. That's where the CBM system steps in. With it’s ability to boost bed temperatures and adjust char bed profiles it ensures boilers run safely and smoothly.

And it's not just about preventing overloads. The CBM system also helps cut down on carryover and blockages by spreading liquor spray more effectively onto the bed. Plus, with hotter beds, we can dial up boiler water circulation ratios for even better performance. It's all about staying up-to-date and ensuring our boilers can handle whatever comes their way.